Since its establishment in 2010, Hong-Gin International has been upholding the spirit of professionalism, enthusiasm, and customers first to provide perfect services to our customers and insists on mutual trust to establish a good reputation in the industry. In 2013, Hong-Gin International invested in the production of non-iodine and environmentally friendly fully dyed polarized films and has continued to develop a number of fully dyed polarized products and applying them to various fields of optical products to create higher added-value for our customers. In the industry, we are actively moving towards full product integration and developing new products to meet the different needs of customers in various markets to achieve the goal of sustainable management.

Natural light is actually composed of electromagnetic waves that vibrate in a specific direction. The light that is reflected or scattered usually prefers a specific direction, so when a polarizing lens filters natural light, only one direction of light is allowed to pass through. In other words, the polarizing lens can first polarize the light and then allow only one direction of light to pass through (visible light).

Polarized sunglasses use this feature to block out harmful light. Polarized sunglasses safely absorb this glare, which can cause dazzle and eye damage, as sunlight is naturally reflected or refracted from any object it touches. This is why polarized sunglasses can filter out the sunlight reflected from car roofs or pools. Therefore, the filtered view with polarized materials reduces the light's glare, dazzle, and curvature, especially when reflected. When the light is filtered with a polarizing plate, it reduces glare and extends the viewing distance.

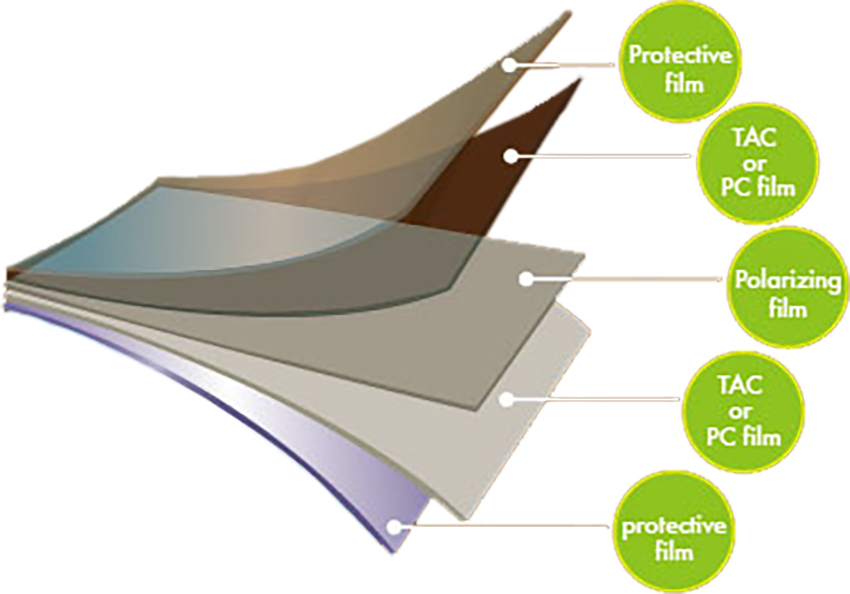

The structure of a polarizer is shown in the diagram and consists of a protective film, TAC or PC, PVA and other structures. The protective film is used to protect the surface of the polarizer and should be removed by the customer when in use. TAC or PC is used to fix and protect the PVA so that it is not brittle and shrinkable and can block the optics from moisture and provide different surface treatments. PVA is the main body used to produce polarized light.

Taiwan is the world's seventh largest country dies market in recent years, is facing price competition, resulting in the relocation industry.

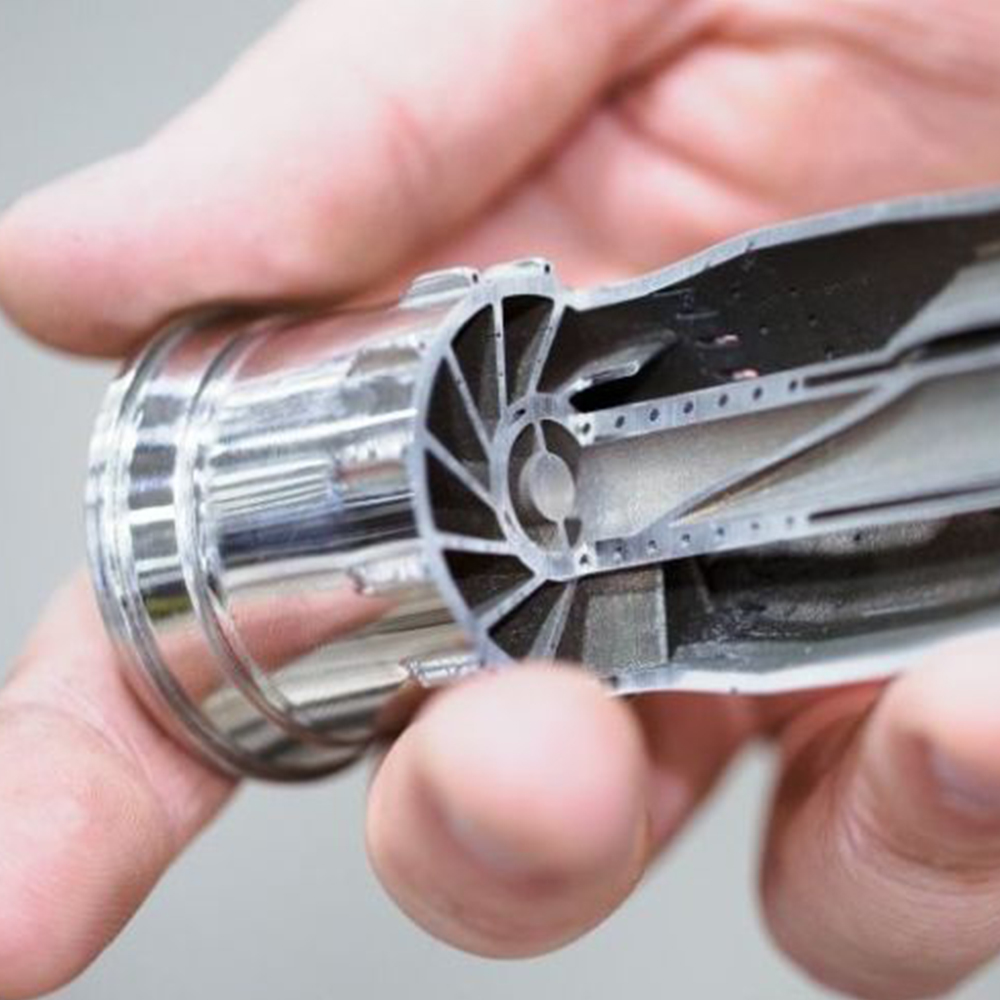

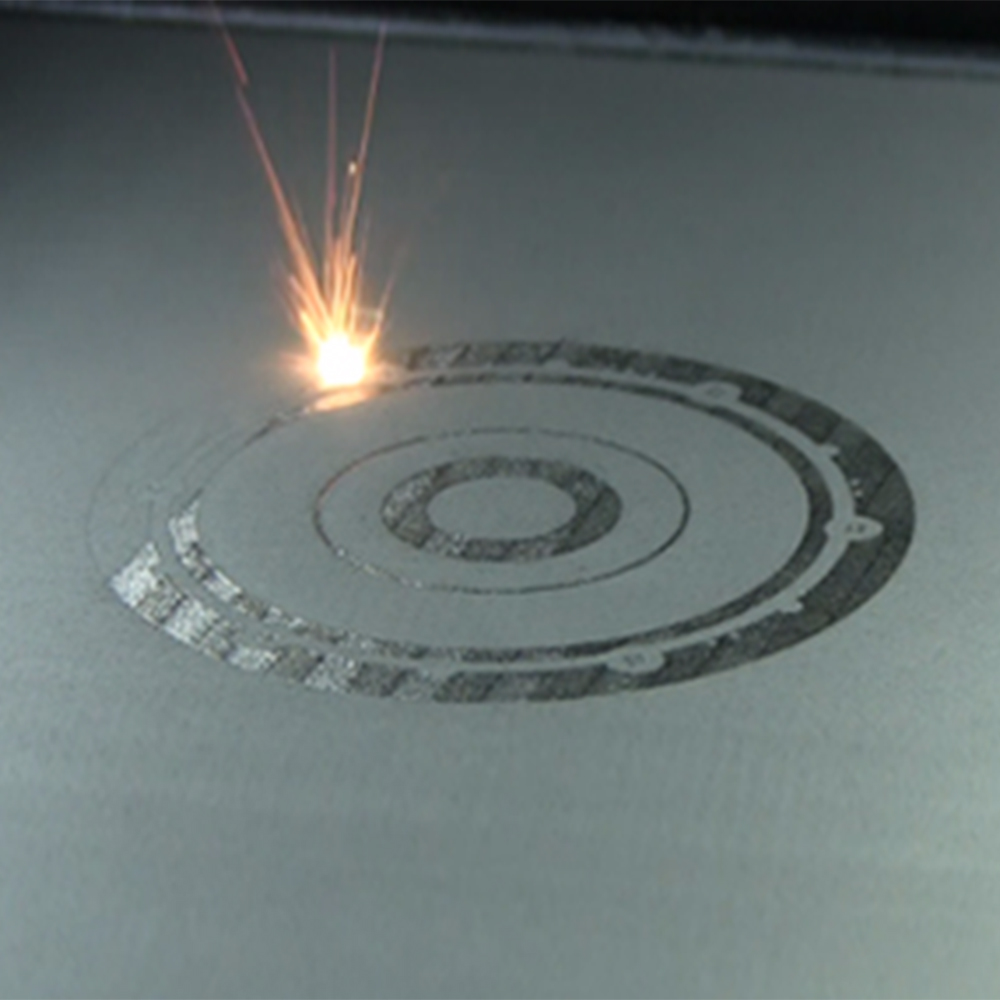

On metal, increasingly sophisticated 3D printing technology, will be the turning point in Taiwan mold industry! Waterway through a special design, the cooling rate, but also enhance production efficiency, the opportunity for Taiwan's mold industry more distinctive. When 3D printing technology matures, it will be an important opportunity to flip the mold industry.

"For industry, mold, 3D printing is the second industrial revolution," a professional model and rapid tooling behalf of the industry, the first mold revolution in the 1950s, the United States and Japan have started to develop a computer numerical control machine tools (Computer Numerical control, CNC), a computer program to control the mechanical cutting mold, more accurate and faster.

Taiwan is the 1980s began to develop and use. But regardless of the traditional way or CNC, in the production of molds are taken, "the concept of subtraction," which is cut with a knife cut, cut, drill, dig a desired shape, and then cooled again to heat the way a lot of rapid prototyping products. Throughout the molding process, the cooling time is about 40% to 90%, generally will use water or other cooling medium is circulated around the mold, so the design of the cooling water, to check that the production becomes stable quality key. However, cutting of the way, the traditional mold cooling circuit design caused a lot of restrictions.

Metal 3D printing technology base to help mold industry upgrading."In the future mold industry will move toward a single scale, the small amount of diversity, a higher level, the ultimate production." Metal 3D printing systems and technologies widely used in automotive, hardware tools, 3C consumer electronics, home appliances, medical and so on ....